Dye Sublimated Patches

These are created through a print process called dye sublimation. It is accomplished by printing a special ink onto transfer paper, applying that paper to a substrate and then applying heat and pressure to the material. The result is a soft-hand print and excellent color reproduction. High levels of detail along with high color count designs can be achieved where screen printing and embroidery fall short. This decoration method can be used by itself or in combination with both embroidery and/or screen printing for a unique mixed media result.

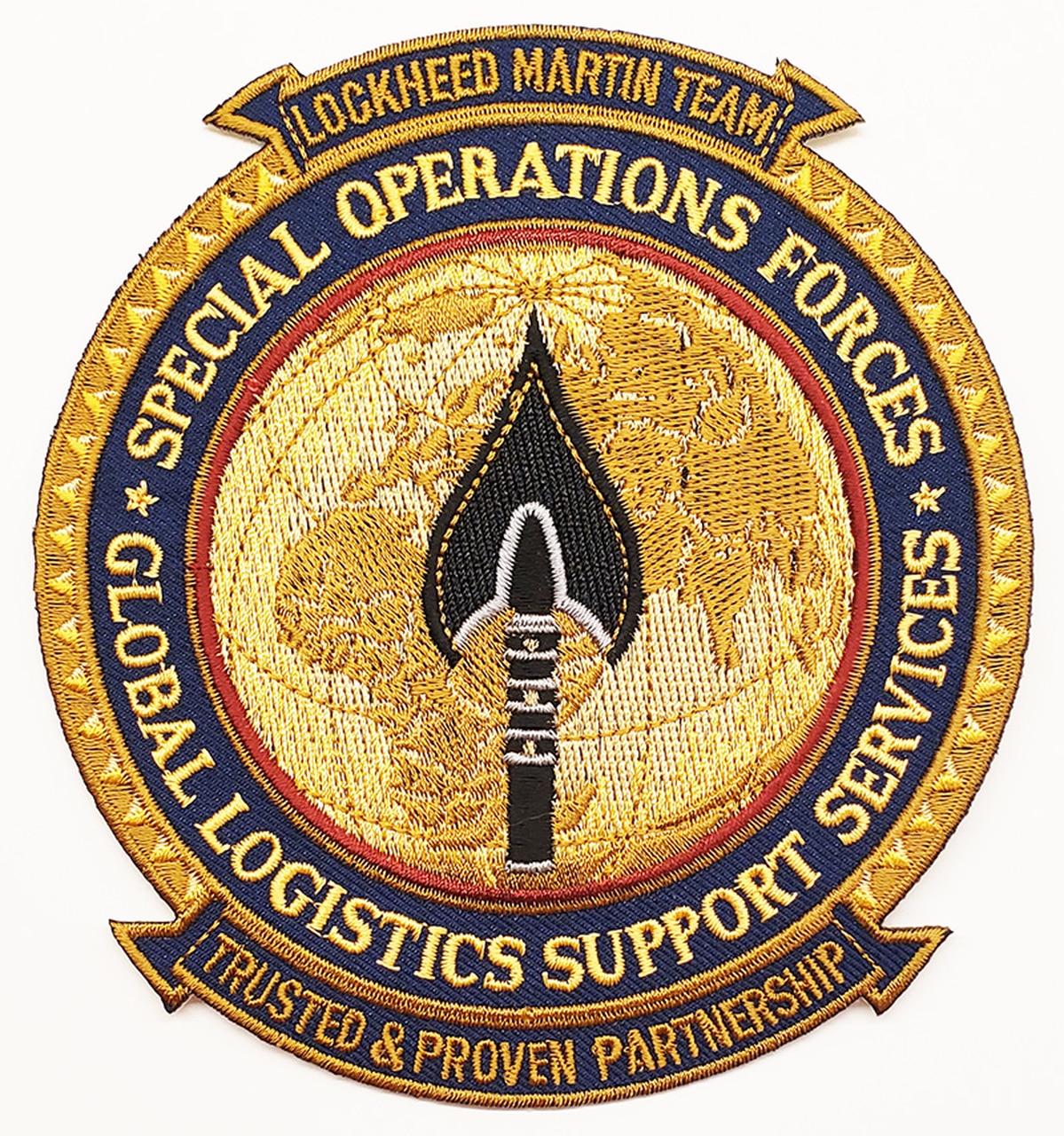

Embroidered Patches

Embroidered patches are one of the most popular types of patches and can be produced in any shape or size. Embroidery does however have its limitations in regards to fine detail (see HERE). For the letters to be legible, the size of letters should be at least 3/16” high on twill background, or 1/4” high on heavier fabric background. This decoration method can be used by itself or in combination with dye sublimation for a unique mixed media result.

Custom Pantone colors can be match for the twill fabric backing but may require higher minimums and a longer turnaround time.

Dye Sublimated/Embroidered Patches

These patches combine 2 very popular patch processes, Dye Sublimation and Embroidery. Separately both processes have their limitations but together, they can produce a wide variety of customizable patches. The background is dye sublimated with embroidery added on top giving your design extra dimension and texture.

Screen Printed Patches

Screen printed patches are printed onto lots of twill fabric and then cut with a laser into the desired shape and size. All screen print mediums can be used from standard flat plastisol prints to high density, puff, foil and water based inks. This decoration method can be used by itself or in combination with dye sublimation or embroidery for a unique mixed media result.

Custom Pantone colors can be match for the twill fabric backing but may require higher minimums and a longer turnaround time.

Woven Patches

Woven patches have a slightly different look to embroidered patches. Our woven patches are used to create a complex two dimensional look. We use a 100% tight woven thread count which is used for designs with the fine detail, gradients, landscapes and very small lettering. They can be made in a standard shape or die cut to a custom shape. We also offer custom backing options such as heat seal, iron on, pressure sensitive and Velcro.

Rubber/PVC Patches Patches

Custom Rubber/PVC patches are made to order, cut your very own custom shape with a sewable border for easy placement on any and all products. These patches are affordable, durable and can be done in either 2D or 3D

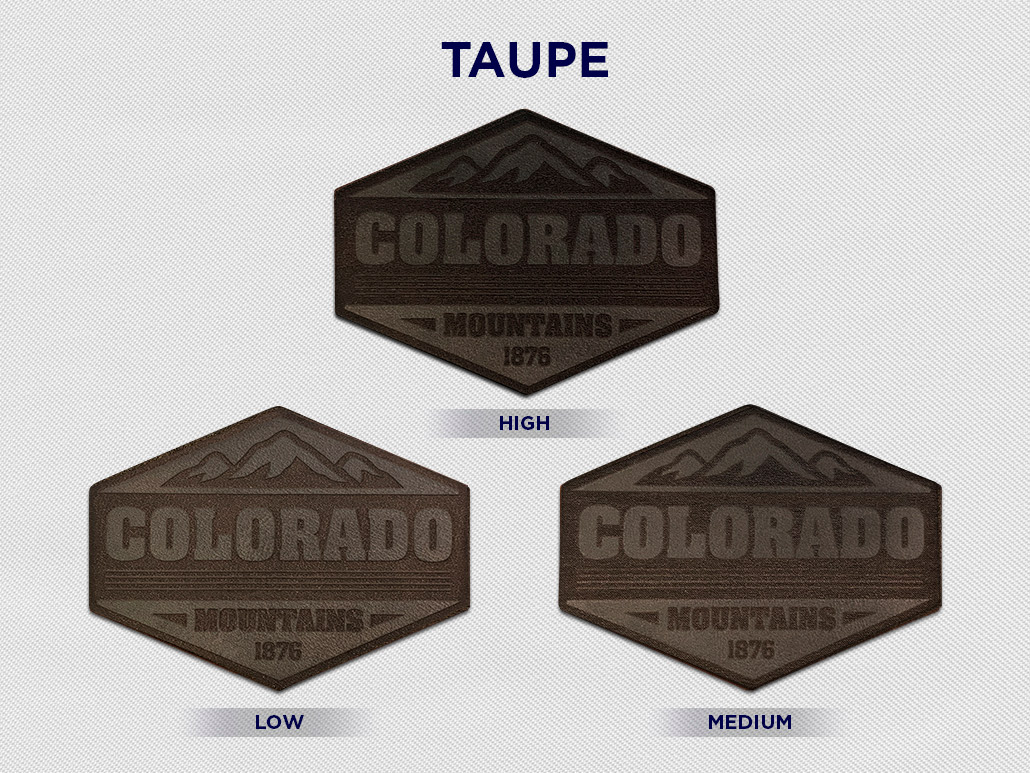

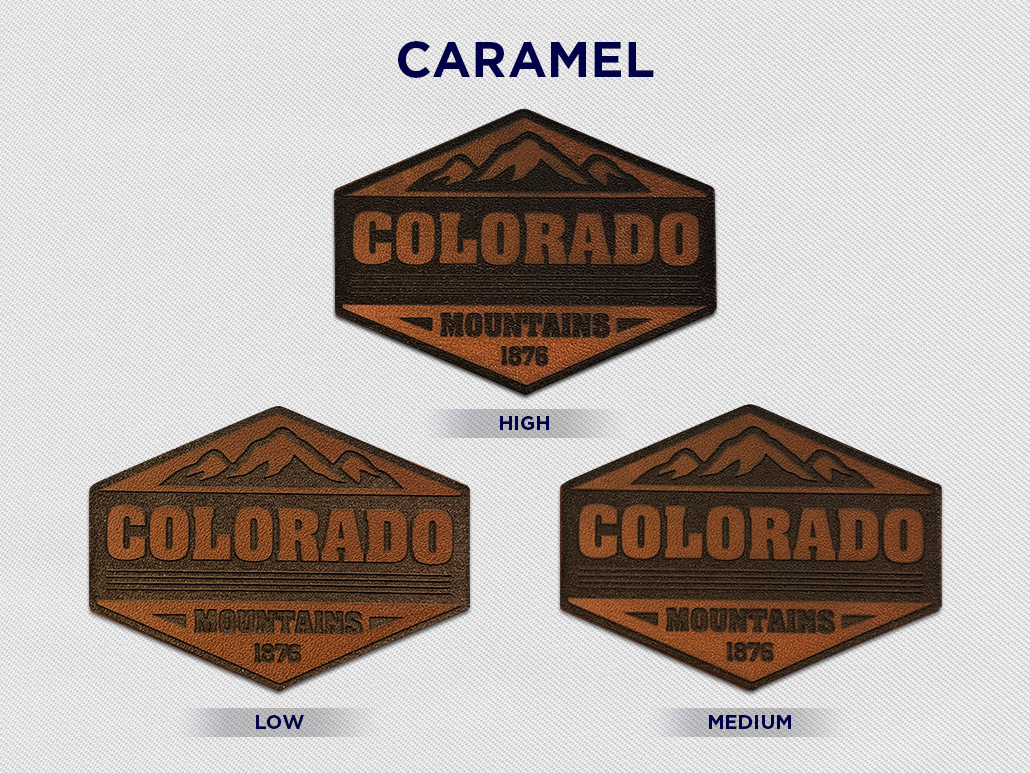

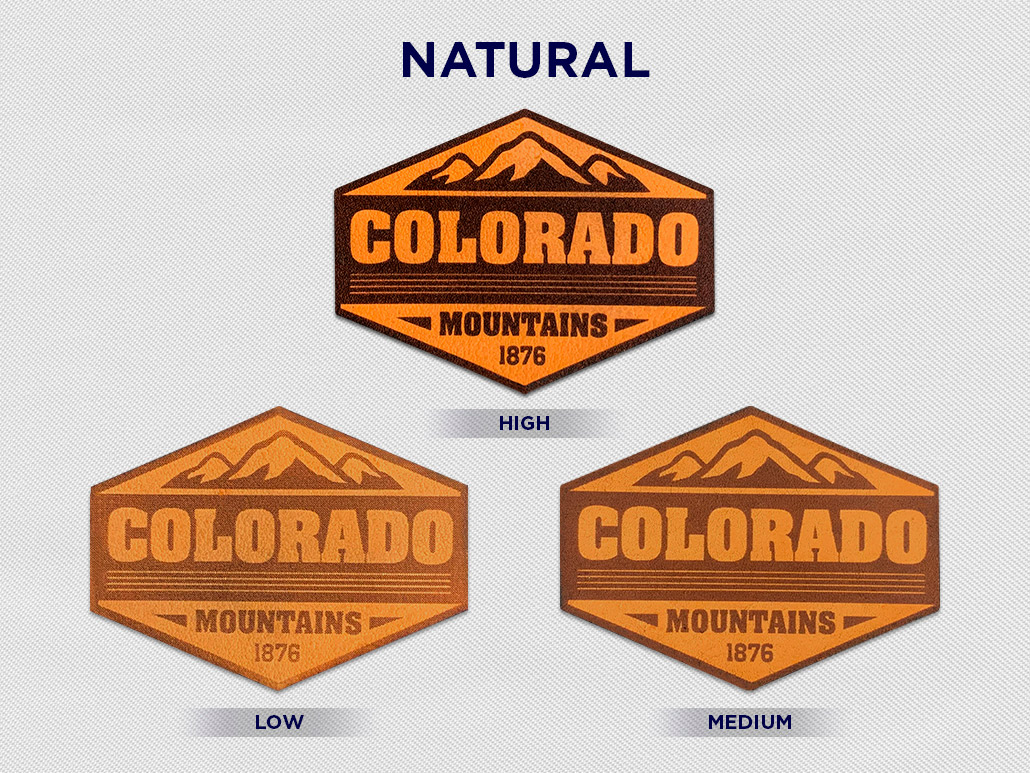

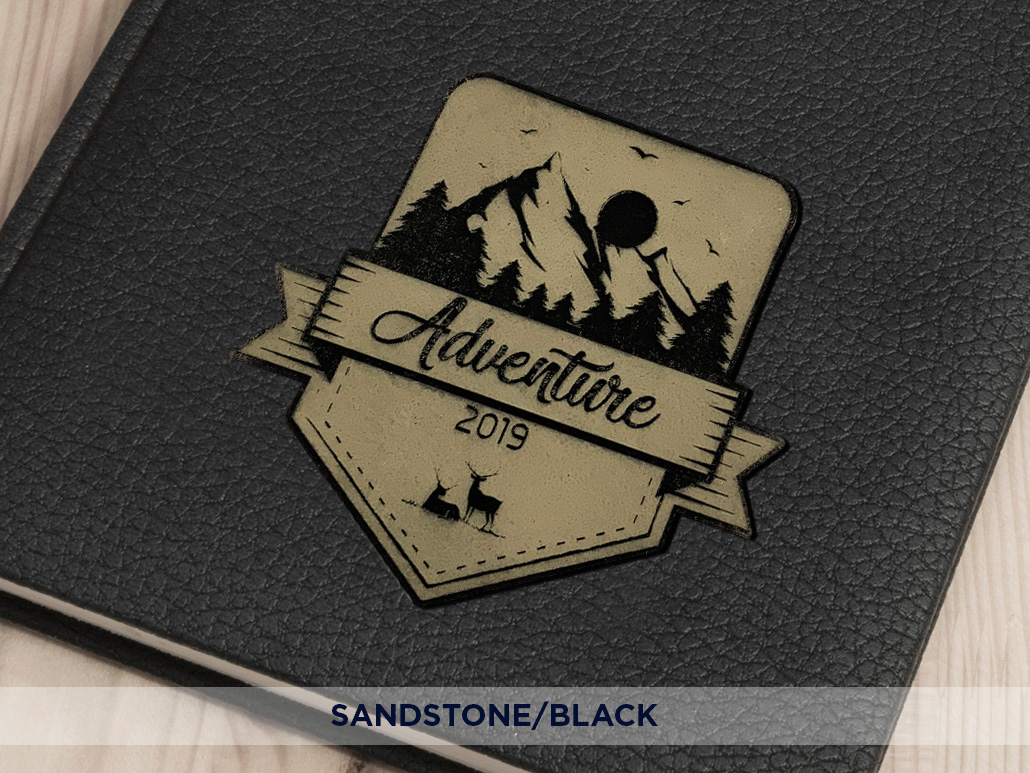

Leather/Faux Leather/Suede Patches

These patches pop with a dimensional look and feel with your design debossed and/or laser engraved into the material. There are two different leather patch options to choose from as well as multiple colors of each:

- Traditional Leather

- Caramel

- Natural

- Taupe

- Faux Leather

- Sandstone/Black

- Black/Silver

- Chestnut/Black

- Chocolate/Black

- Sandstone/Black

FlexStyle Holographic Patches

FlexStyle Holographic emblems use animation to bring your design to life. These eye catching emblems will be sure to get your customers attention.

FlexStyle decorations can be applied to almost any product from garments to hard goods. This is due to the two different backing options:

- 3M - Sticker like backing.

- Heat Transferable - Glue backing activated by heat.

Patch Backings

No Backing

Patches without backings do not have the same thickness or stiffness as patches with backings; therefore, The best time to order No Backing patches is to sew them to clothing or other types of fabrics The back of your patch will be exposed and no backing will be applied during splicing. Patches with no backing are very flexible and lightweight.

Wax Backing

An added layer of wax is applied to back side of the patch for added rigidity to help maintain a level of stiffness

Heat Seal/Iron On Backing

Iron On backing for patches –It’s a fast and easy way to attach. Just put the patch on the clothing and cover it with a thin wet towel to prevent scalding. Then take the iron on the patch for 15-30 seconds until it is fully seated. Iron on backing provides an easy way to attach patches to almost any type of material. A standard home iron with a temperature of 302oF can be used to connect iron blocks for 5-8 seconds When you use ironing support on a patch, you only receive temporary security because it does not last long and we do not recommend using a hot press to apply the hot stamp. Iron On backings are perfect for ceremonial and casual wear, but never use it for any type of practice or training. As you know, Iron on backings are mainly used to safely place the patch during the sewing process, so iron on backing is not the best choice if you want to use it for active lifestyle purposes.

Velcro Backing

Our Velcro backing with high quality, hook & loop design. Velcro backings come with a hook-and-sew seam to your patch and a soft side ready to sew to your clothes. Size up to 4.5″. If you need to change new patches frequently or make other minor adjustments (such as military and police uniforms), hooks are the best option. But if there are no connectors on the clothes, we can use double-sided Velcro in this process.

Adhesive (Peel-and-Stick) Backing

Tap/Adhesive Backing for patches–Easily removable, versatile, and less permanent than other backings, tape backing is great for when you need a quick option for a costume or outfit. As the Adhesive backing is very convenient, making it one of the most popular and familiar backing for embroidered patches. and the background process is very simple. Although adhesive backing is the best choice for you, it has its disadvantages if you want to use it for a long time.

-545x366.PNG)

-528x497.PNG)

-455x452.PNG)

-547x494.PNG)

-546x525.PNG)